Injection Molding Introduction

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold cavity. The process is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. The versatility of the injection molding process allows for the production of complex shapes with high precision and repeatability.

The history of injection molding dates back to the late 19th century, with the first patent filed in 1872 by John Wesley Hyatt. Over the years, the technology has evolved significantly, with modern machines capable of producing millions of identical parts with tight tolerances. Today, injection molding is a cornerstone of the plastics industry, enabling mass production of components for automotive, aerospace, medical, consumer goods, and many other sectors.

The basic principle of injection molding involves several key stages: clamping, injection, dwelling, cooling, and ejection. Each stage is critical to the quality of the final product. The injection mold itself is a precision tool, typically made from hardened steel or aluminum, designed to form the exact shape of the desired part.

Modern injection molding processes leverage advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and robotics to optimize efficiency, reduce waste, and improve part quality. As sustainability becomes increasingly important, the industry is also developing new techniques for using recycled materials and reducing energy consumption in the injection molding process.

Key Benefits of Injection Molding

- High production efficiency and scalability for mass production

- Excellent precision and repeatability in part manufacturing

- Ability to produce complex geometries with tight tolerances

- Wide material selection including thermoplastics, elastomers, and composites

- Reduced waste compared to other manufacturing processes

Injection Process Parameters & Influencing Factors

The injection molding process relies on precise control of several key parameters to produce high-quality parts consistently. These parameters interact with each other, and adjusting one often requires compensating adjustments to others. Proper parameter setting is essential for optimizing cycle time, minimizing defects, and ensuring part quality.plastic injection molding.

Injection speed is one of the most critical parameters, determining how quickly molten plastic fills the injection mold cavity. Too slow, and the material may cool prematurely; too fast, and it can cause excessive shear stress or air entrapment. Modern machines offer multiple speed profiles, allowing for different filling rates in different sections of the mold.

Temperature control is another vital aspect, affecting both the molten plastic and the mold itself. Barrel temperatures must be precisely controlled to ensure proper melting without degradation, while mold temperatures influence cooling rates and part dimensions. Different materials require specific temperature profiles to achieve optimal flow and part quality.

Injection pressure must be sufficient to overcome flow resistance and completely fill the mold cavity. Packing pressure and time are also critical, as they ensure that material continues to flow into the mold as the plastic cools and shrinks. Holding pressure too long can cause excessive stress in the part, while insufficient pressure may result in incomplete filling or sink marks.

Other important parameters include cooling time, which affects cycle time and part stability; screw rotation speed, which influences melting efficiency; and back pressure, which affects melt homogeneity. The optimal parameters for any given application depend on factors such as material properties, part geometry, mold design, and desired part characteristics.

Primary Parameters

- Melt & Mold Temperature

- Injection Speed & Pressure

- Cycle Time & Cooling

- Packing & Holding Pressure

Influencing Factors

- Material Properties

- Mold Design & Complexity

- Part Geometry & Thickness

- Machine Capabilities

Injection Molding Defects & Improvement Strategies

Identifying common defects and implementing effective solutions is crucial for maintaining quality and efficiency in injection molding production.injection molded plastic.

Sink Marks & Voids

Causes: Inadequate packing pressure, uneven cooling, excessive wall thickness, insufficient hold time, or material shrinkage.

Solutions: Increase packing pressure and time, optimize cooling system, ensure uniform wall thickness in design, adjust melt temperature, or select materials with lower shrinkage rates.

These defects often appear as depressions on the surface, typically opposite thick sections in the part.

Flash

Causes: Excessive injection pressure, insufficient clamping force, worn mold components, misaligned mold, or too high melt temperature.

Solutions: Reduce injection pressure, increase clamping force, maintain and repair injection mold components, ensure proper mold alignment, or lower melt temperature.

Flash appears as excess material protruding from the part along the mold parting line.

Warpage & Distortion

Causes: Uneven cooling, residual stresses, non-uniform wall thickness, improper gate location, or incorrect material selection.

Solutions: Optimize cooling system, adjust packing pressure and cooling time, redesign for uniform thickness, reposition gates, use stress-relief annealing, or select more dimensionally stable materials.

Warpage refers to the unwanted deformation of parts after ejection from the mold.

Burn Marks

Causes: Trapped air in the mold cavity, excessive melt temperature, slow filling speed, inadequate venting, or prolonged residence time in the barrel.

Solutions: Improve mold venting, reduce melt temperature, increase injection speed, optimize gate location, reduce back pressure, or shorten cycle time.

Burn marks appear as discolored, often blackened areas where material has overheated or burned.

Systematic Approach to Defect Resolution

Identify & Document

Thoroughly inspect and document the defect, noting its location, appearance, and frequency. Use visual aids and measurements for accuracy.

Analyze Root Cause

Use systematic problem-solving techniques to determine the underlying cause, considering material, machine, mold, and process variables.

Implement & Verify

Apply targeted solutions, monitor results, and verify effectiveness. Document successful resolutions for future reference.

"Effective defect management requires a combination of technical knowledge, systematic investigation, and continuous improvement. By understanding the relationship between process parameters, material behavior, and injection mold performance, manufacturers can minimize defects and optimize production efficiency."

Special Injection Molding Processes

Beyond conventional injection molding, several specialized processes have been developed to meet specific manufacturing challenges and produce complex, high-performance components. These advanced techniques expand the capabilities of plastic processing, enabling the production of parts with unique properties or complex geometries that would be difficult or impossible to achieve with standard methods.metal injection molding.

Multi-shot injection molding, also known as overmolding, involves molding two or more different materials or colors in a single process. This technique produces parts with multiple components in one operation, eliminating the need for assembly. The process requires specialized machines and molds, often with rotating platens or indexable mold sections to position the part correctly for each shot.

Gas-assisted injection molding injects an inert gas (typically nitrogen) into the molten plastic during the molding process. The gas displaces the molten material, creating hollow sections while maintaining structural integrity. This results in parts with reduced weight, improved dimensional stability, and minimized warpage. Gas-assisted molding is particularly useful for large parts with thick sections.

Micro-injection molding specializes in producing extremely small parts, often with dimensions measured in microns. This precision process requires specialized equipment with exceptional control systems and high-precision injection mold tools. Micro-molding is widely used in medical devices, electronics, and other applications requiring miniature components.

Other specialized processes include structural foam molding, which produces lightweight parts with a cellular core and solid skin; insert molding, which encapsulates metal or other components within the plastic part; and in-mold decoration, which applies labels or finishes during the molding process. Each of these techniques offers unique advantages and requires specific expertise in machine operation, material selection, and mold design.

Applications of Special Processes

Automotive Industry

Multi-shot molding for soft-touch grips, gas-assisted molding for large structural components, and insert molding for integrated metal-plastic parts.

Medical Devices

Micro-injection molding for tiny components, multi-material molding for ergonomic handles, and cleanroom molding for sterile applications.

Consumer Electronics

In-mold decoration for high-end finishes, insert molding for integrated components, and precision molding for miniature parts.

Packaging Industry

Structural foam molding for lightweight containers, multi-layer molding for barrier properties, and in-mold labeling for decorated packaging.

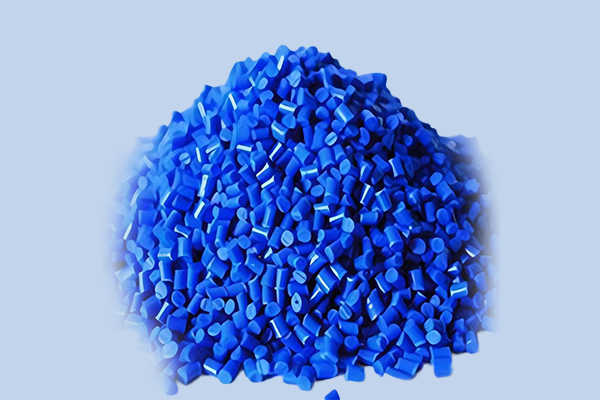

Common Plastics Used in Injection Molding

Selecting the right material is critical for achieving desired part properties, performance, and cost-effectiveness in injection molding.injection molding of plastics.

Polypropylene (PP)

A versatile, cost-effective thermoplastic with excellent chemical resistance and good impact strength.

Common Applications

Automotive components, packaging, consumer goods, medical devices, and industrial parts.

Polyethylene (PE)

A family of lightweight, flexible plastics with excellent chemical resistance and low moisture absorption.

Common Applications

Containers, bottles, toys, pipes, and flexible components requiring impact resistance.

Acrylonitrile Butadiene Styrene (ABS)

A tough, rigid thermoplastic with good impact resistance and dimensional stability.

Common Applications

Automotive parts, electronic enclosures, toys, consumer appliances, and 3D printing.

Polyamide (PA/Nylon)

A strong, durable thermoplastic with excellent wear resistance and low friction properties.

Common Applications

Gears, bearings, structural components, automotive parts, and electrical insulators.

Polycarbonate (PC)

A transparent, high-performance plastic with exceptional impact strength and heat resistance.

Common Applications

Safety glasses, medical devices, electronic components, automotive lighting, and impact-resistant windows.

Polyethylene Terephthalate (PET)

A strong, lightweight plastic with excellent barrier properties and recyclability.

Common Applications

Beverage bottles, food containers, fibers, and engineering components when reinforced.

Material Selection Considerations

Performance Requirements

- Mechanical properties (strength, flexibility, impact resistance)

- Thermal resistance and operating temperature range

- Chemical resistance to fluids, solvents, and environmental factors

- Electrical properties (insulation, conductivity requirements)

- UV resistance and outdoor durability if applicable

Processing & Economic Factors

- Melt flow characteristics and suitability for the injection mold design

- Material cost and availability for production volumes

- Recyclability and environmental considerations

- Colorability and surface finish requirements

- Regulatory compliance for specific industries (medical, food contact)

Injection Molding Equipment

Injection molding equipment encompasses a range of machines and auxiliary systems designed to transform plastic resin into finished parts through the injection molding process. The primary component is the injection molding machine, which works in conjunction with the injection mold to produce parts efficiently and consistently.Injection molding machine.

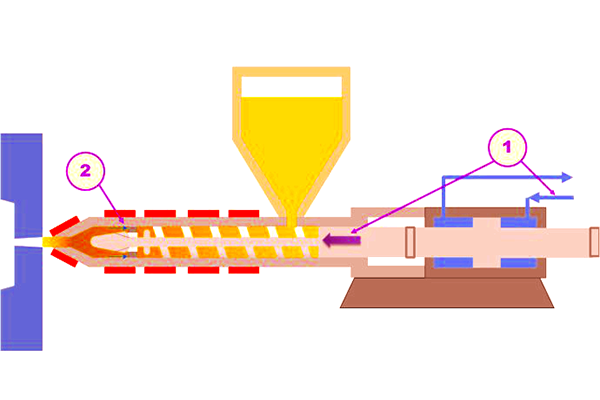

Modern injection molding machines consist of three main components: the injection unit, the clamping unit, and the control system. The injection unit is responsible for melting and delivering the plastic material, while the clamping unit secures and opens the mold. The control system precisely regulates all machine parameters to ensure consistent part quality.

Machine sizing is typically determined by clamping force, measured in tons, which ranges from a few tons for micro-molding machines to several thousand tons for large industrial machines. The appropriate machine size depends on the part size, projected area, and material requirements.

Auxiliary equipment plays a crucial role in the injection molding process, including material handling systems, dryers, mold temperature controllers, chillers, and robots for part removal. These systems enhance efficiency, improve quality control, and enable automation of the production process.

Recent advancements in injection molding equipment include improved energy efficiency, enhanced control systems with artificial intelligence capabilities, and increased connectivity for Industry 4.0 integration. These developments enable better process monitoring, predictive maintenance, and optimization of production parameters for maximum efficiency and quality.

Key Equipment Components

Injection Unit

- Screw and barrel for plasticizing and melting resin

- Nozzle for delivering molten plastic to the mold

- Hopper for material storage and feeding

- Heating elements for temperature control

Clamping Unit

- Moving and stationary platens to hold the mold

- Toggle or hydraulic system for clamping force

- Ejection system to remove parts from the mold

- Guides to ensure precise platen alignment

Control System

- Touchscreen interface for parameter setup

- Sensors and feedback loops for process control

- Data logging and production monitoring

- Recipe storage for different part programs

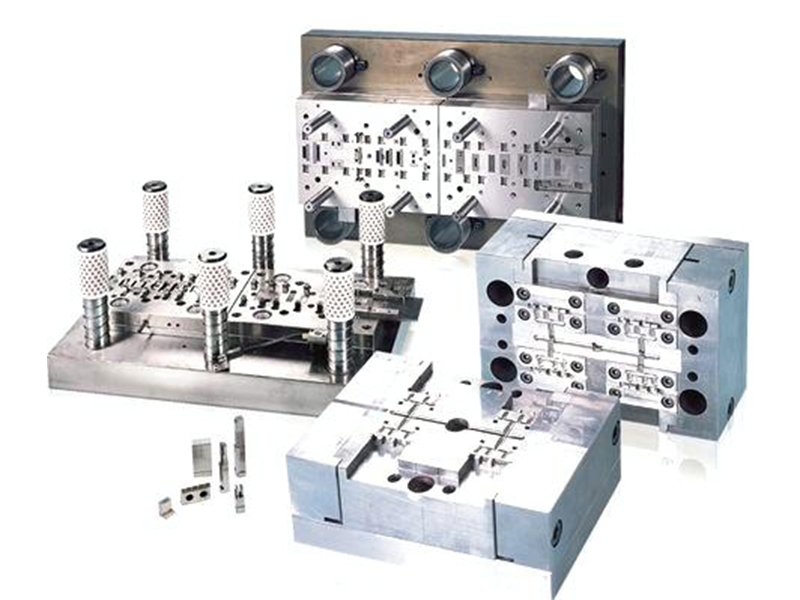

Injection Molds

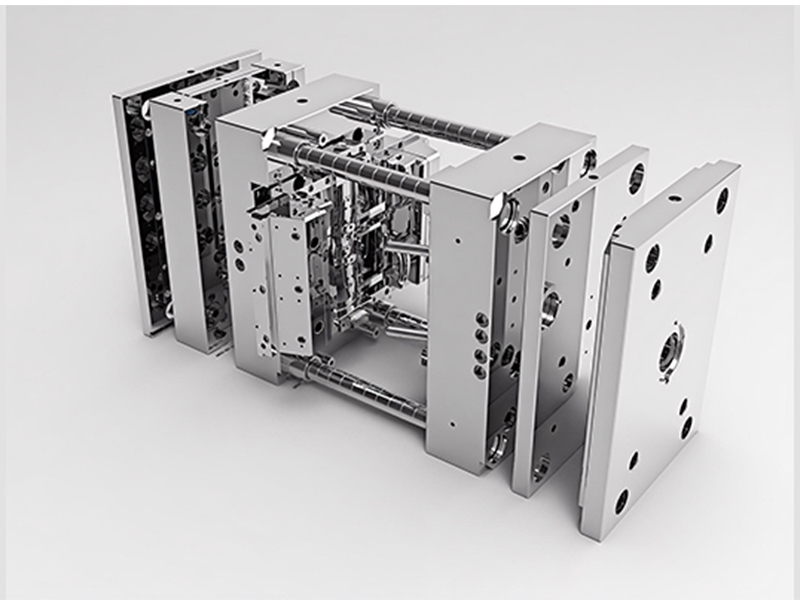

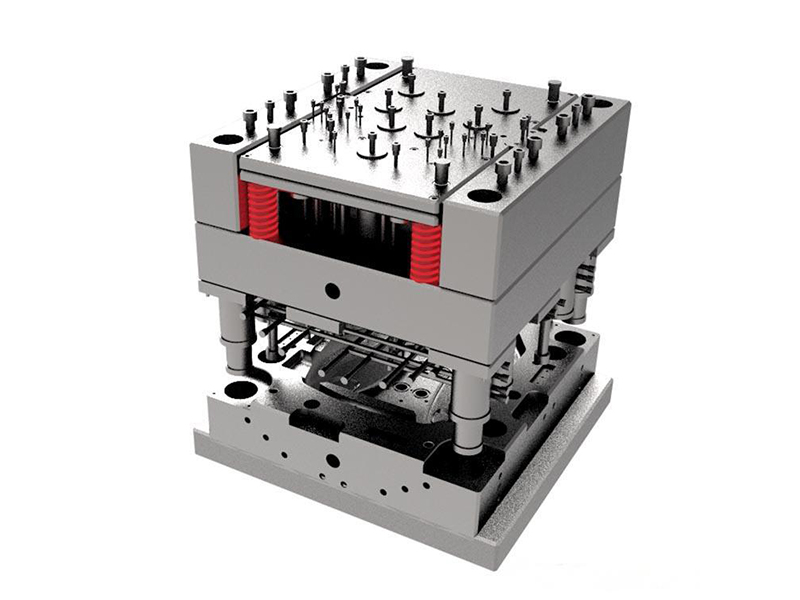

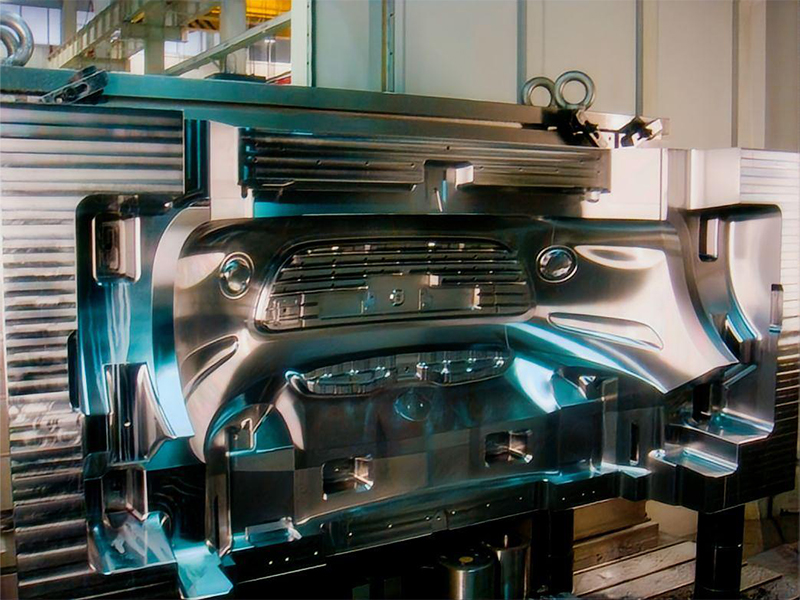

The injection mold is a precision tool that shapes molten plastic into the desired part geometry. Mold design and construction are critical factors in determining part quality, production efficiency, and overall manufacturing costs. A well-designed mold can produce high-quality parts consistently, while a poorly designed mold may result in defects, increased cycle times, and higher production costs.Injection mold.

Injection molds are typically constructed from high-grade tool steel or aluminum, with steel molds offering greater durability and longer lifespans, making them suitable for high-volume production. Aluminum molds, while less durable, can be manufactured more quickly and economically, making them ideal for prototyping or low-volume production runs.

Basic mold components include the cavity and core, which form the part's external and internal geometry respectively; the runner system, which channels molten plastic from the machine nozzle to the cavity; and the gating system, which controls the flow of plastic into the cavity. Ejection systems, cooling channels, and venting are also essential components of a functional injection mold.

Mold design involves careful consideration of part geometry, material properties, cooling requirements, and production volume. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are essential tools in modern mold design, enabling engineers to optimize mold performance, simulate filling patterns, and detect potential issues before manufacturing the mold.

Proper mold maintenance is essential for ensuring consistent part quality and maximizing mold lifespan. Regular cleaning, inspection, and repair of wear components can prevent unexpected downtime and extend the productive life of the mold. Advanced molds may include features such as hot runners, which eliminate runner waste, and collapsible cores, which enable the production of complex geometries with undercuts.

Mold Types

Two-Plate Mold

The most common mold type with a simple design, consisting of a stationary and moving half.

Three-Plate Mold

Features an additional plate to allow for gating away from the part's edge.

Hot Runner Mold

Maintains molten plastic in the runner system, eliminating runner waste.

Stack Mold

Contains multiple mold cavities stacked vertically to double production output.

Mold Design Considerations

Parting Line Placement

Strategic placement to minimize visible lines and simplify mold construction

Gate Design & Location

Optimized for uniform filling, minimal stress, and aesthetic considerations

Cooling System Design

Uniform cooling channels to reduce cycle time and minimize warpage

Ejection System

Properly positioned ejector pins or plates to prevent part damage

Venting

Adequate venting to allow air escape during filling and prevent burn marks

Draft Angles

Proper angles to facilitate easy part ejection and prevent damage

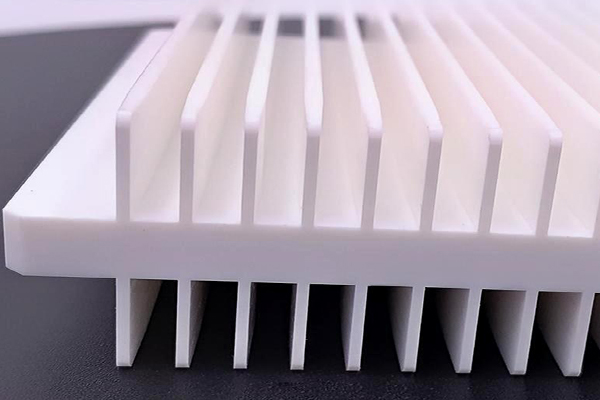

Injection Molded Part Secondary Processing

After ejection from the injection mold, many parts require secondary processing to meet final specifications or prepare them for assembly. Secondary operations can enhance part functionality, improve aesthetics, or add specific features that cannot be achieved through the molding process alone. These processes are an integral part of the manufacturing workflow, ensuring that the final product meets all design requirements.Injected molded plastic.

Trimming and deflashing are among the most common secondary operations, removing excess material such as runners, gates, or flash that may remain on the part after molding. This can be done manually for low-volume production or with automated equipment for high-volume runs, ensuring consistent results and reducing labor costs.

Surface finishing processes improve the aesthetic or functional properties of molded parts. These include painting, which can provide color, texture, or protective coatings; printing, for adding labels, logos, or instructions; and plating, which applies a thin metal layer to enhance appearance or conductivity. Other surface treatments include polishing for a high-gloss finish and texturing to improve grip or hide surface imperfections.

Assembly operations may be required to combine multiple injection molded parts or integrate them with components from other manufacturing processes. This can involve mechanical fastening methods such as screws or snaps, adhesive bonding for permanent joints, or welding techniques specifically designed for plastics, such as ultrasonic welding, vibration welding, or hot plate welding.

Specialized secondary processes include machining operations like drilling, milling, or turning to achieve tight tolerances on specific features; heat treatment for improving material properties; and testing or inspection processes to ensure quality. The selection of appropriate secondary operations depends on part design requirements, material properties, production volume, and cost considerations.

Common Secondary Processes

| Process | Purpose | Common Applications |

|---|---|---|

| Trimming/Deflashing | Remove excess material | All molded parts, especially those with complex geometries |

| Painting | Add color, texture, or protection | Automotive parts, consumer goods, appliances |

| Printing | Apply labels, logos, or text | Packaging, consumer products, medical devices |

| Ultrasonic Welding | Join plastic components | Electronics, automotive, medical devices |

| Machining | Achieve tight tolerances | Precision components, bearing surfaces |

| Plating | Add metal coating | Decorative parts, electrical components |

Secondary Processing Considerations

- Design for manufacturability to minimize secondary operations

- Material compatibility with secondary processes

- Impact on dimensional tolerances and part integrity

- Cost-benefit analysis of automation vs. manual processing

- Environmental considerations for finishing processes

Injection Molding Quality Management

A comprehensive quality management system for plastic injection molding services ensures consistent production of high-quality injection molded parts that meet design specifications and customer requirements.

Quality Control Processes

Incoming Inspection

Verification of raw materials, ensuring they meet specified requirements before entering production. This includes checking material certificates, performing moisture content analysis, and verifying resin identification.

In-Process Monitoring

Continuous monitoring of the injection molding process parameters to ensure they remain within specified ranges. This includes real-time data collection and analysis of temperature, pressure, and cycle time variables.

Part Inspection

Dimensional and visual inspection of molded parts using tools such as calipers, micrometers, gauges, and coordinate measuring machines (CMM). Statistical sampling plans determine inspection frequency based on part criticality.

Final Validation

Comprehensive testing of finished products to ensure they meet all functional and performance requirements. This may include mechanical testing, environmental testing, and functional verification.

Quality Management Systems

ISO Standards

Implementation of international quality standards such as ISO 9001 for general quality management, ISO 13485 for medical device manufacturing, and IATF 16949 for the automotive industry.

Statistical Process Control (SPC)

Use of statistical methods to monitor and control the injection molding process, identifying variations before they result in defects. Control charts track key parameters and trigger corrective actions when out-of-control conditions occur.

Corrective & Preventive Action (CAPA)

Systematic approach to addressing quality issues, including root cause analysis, implementation of corrective actions, and development of preventive measures to avoid recurrence.

Quality Culture

Fostering a workplace culture where quality is everyone's responsibility, with employee training, empowerment, and involvement in continuous improvement initiatives.

Key Quality Metrics

First Pass Yield (FPY)

Percentage of parts that meet quality standards without rework

Target: >90%

Defects Per Million Opportunities (DPMO)

Measure of process capability and quality performance

Target: <200

Process Capability (Cpk)

Statistical measure of process capability to meet specifications

Target: >1.33

Customer Rejects

Percentage of shipped parts rejected by customers

Target: <0.5%

Advanced Quality Tools

Machine Vision Inspection

Automated systems that use cameras and image processing to detect surface defects, verify dimensions, and ensure part consistency at production speeds.

Process Simulation

Computer-aided engineering tools that simulate the injection molding process to predict and prevent potential quality issues before mold construction.

Digital Quality Records

Electronic systems for documenting quality data, facilitating traceability, analysis, and continuous improvement of both the injection mold performance and molding processes.

Predictive Quality Analytics

Advanced data analytics that identify patterns and predict potential quality issues before they occur, enabling proactive corrective actions.

Injection Molding Production Management

Effective production management is essential for optimizing injection molding operations—by streamlining the operation, maintenance, and scheduling of core equipment like the injection molder—ensuring efficient use of resources, meeting production schedules, and maintaining profitability. This involves coordinating all aspects of the manufacturing process, from material procurement to finished goods delivery, while continuously improving productivity and quality.

Production planning and scheduling form the foundation of successful manufacturing operations. This includes determining optimal production sequences, allocating machine resources, and establishing realistic production targets based on customer demand. Advanced planning software can help optimize schedules, minimize changeover times between production runs, and maximize overall equipment effectiveness (OEE).

Resource management encompasses the efficient utilization of personnel, machines, and materials. This includes ensuring proper staffing levels with appropriately trained personnel, maintaining equipment in good working condition through preventive maintenance programs, and managing material inventory to avoid shortages or excess stock. Effective resource management directly impacts production efficiency and costs.

Process optimization focuses on reducing cycle times, minimizing waste, and improving overall productivity. This involves analyzing production data to identify bottlenecks, implementing lean manufacturing principles to eliminate non-value-added activities, and continuously improving molding processes through systematic experimentation and documentation. The goal is to achieve consistent, high-quality production at the lowest possible cost.

Modern production management leverages digital technologies such as manufacturing execution systems (MES), Internet of Things (IoT) sensors, and data analytics to provide real-time visibility into production operations. These tools enable better decision-making, faster response to production issues, and more accurate forecasting. Integration of these systems with enterprise resource planning (ERP) software creates a seamless flow of information across the organization, from order entry to production to shipping.Optical Transceiver.

Key Production Management Areas

Planning & Scheduling

- Optimal production sequencing to minimize changeovers

- Capacity planning based on machine capabilities and demand

- Real-time schedule adjustments to address disruptions

- Balancing workload across production cells

Equipment Maintenance

- Preventive maintenance schedules for machines and injection mold tools

- Condition monitoring using sensors and predictive analytics

- Efficient spare parts inventory management

- Root cause analysis for equipment failures

Performance Monitoring

- Overall Equipment Effectiveness (OEE) tracking

- Production metrics dashboards with real-time data

- Downtime analysis and reduction initiatives

- Continuous improvement through Kaizen events

Optimize Your Injection Molding Operations

Whether you're looking to improve quality, reduce costs, or enhance productivity in your injection molding processes, our expertise can help you achieve your goals.Electronic shelf labels.