Factors Influencing Injection Molding Parameter Settings

Understanding the complex interplay of factors that affect injection molding parameters is crucial for optimizing production quality, efficiency, and controlling injection molding cost. This comprehensive guide explores the key elements that influence parameter settings and their practical implications for manufacturing processes.

I. Shrinkage Rate

Shrinkage is a critical factor in injection molding that significantly impacts part dimensions and quality. Controlling shrinkage properly can reduce waste and minimize injection molding cost by ensuring parts meet specifications on the first production run.

1. Plastic Material Type

During the molding process of thermoplastic materials, volume changes occur due to crystallization, strong internal stress, significant residual stress "frozen" in the injection-molded part, and strong molecular orientation. These factors result in higher shrinkage rates compared to thermosetting plastics.

Thermoplastics exhibit a wider range of shrinkage rates with more pronounced directional characteristics. Additionally, shrinkage that occurs after molding, annealing, or humidity conditioning is generally greater than that of thermosetting plastics. Proper material selection can help manage these factors and control injection molding cost by reducing post-processing requirements.

2. Part Structural Characteristics

The presence of inserts in injection-molded parts, as well as their layout and quantity, directly affect material flow direction, density distribution, and shrinkage resistance. Consequently, the structural characteristics of the injection-molded part have a significant impact on shrinkage magnitude and directionality.

Complex geometries with varying wall thicknesses can create uneven shrinkage patterns, which may require adjustments to molding parameters. Designing parts with uniform wall thicknesses where possible can improve shrinkage consistency and help control injection molding cost by reducing the need for parameter adjustments and rework.

3. Gate Type, Size, and Distribution

- Influence on material flow direction: The gate design affects how molten plastic fills the cavity, which in turn impacts density distribution, packing pressure effectiveness, and molding cycle time – all factors that influence injection molding cost.

- Direct gate considerations: For direct gates, a larger gate cross-section (especially one with significant thickness) results in lower shrinkage. This is because larger gates allow better pressure transmission during packing, reducing the need for excessive material usage that would increase injection molding cost.

- Shrinkage gradient: Areas near the gate exhibit lower shrinkage rates, while areas farther from the gate experience higher shrinkage. This creates a gradual shrinkage gradient from the gate to the farthest point of the part. Proper gate placement can minimize this gradient and reduce potential warpage, which helps control injection molding cost by reducing scrap rates.

4. Injection Molding Conditions

Molding conditions play a crucial role in determining final part shrinkage. Optimizing these parameters not only ensures part quality but also contributes to minimizing injection molding cost by reducing waste and improving cycle times.

Injection Pressure

With constant molding temperature, increased injection pressure reduces shrinkage rate. This can help maintain dimensional accuracy without increasing injection molding cost through material waste.

Packing Pressure

Increased packing pressure reduces shrinkage rate by ensuring better compensation for material contraction during cooling, which is essential for controlling injection molding cost related to part rejection.

Melt Temperature

Increased melt temperature slightly reduces shrinkage rate but must be balanced with energy costs to maintain optimal injection molding cost.

Mold Temperature

Higher mold temperatures increase shrinkage rate. Controlling mold temperature precisely is key to managing both quality and injection molding cost.

Packing Time

Extended packing time reduces shrinkage rate but may increase cycle time, affecting injection molding cost efficiency.

Cooling Time

Longer in-mold cooling time reduces shrinkage rate. Optimizing cooling time balances quality requirements with injection molding cost considerations.

Injection Speed

Increased injection speed slightly increases shrinkage rate, but the effect is generally minimal. However, it can impact cycle time and thus injection molding cost indirectly.

Shrinkage Timing

Shrinkage is greater during injection molding than after demolding. Understanding this timing helps in setting appropriate parameters to minimize dimensional deviations that could increase injection molding cost.

Post-Molding Shrinkage

Post-molding shrinkage is most significant in the first two days and stabilizes after approximately one week. This must be accounted for in design to prevent costly rework and maintain injection molding cost efficiency.

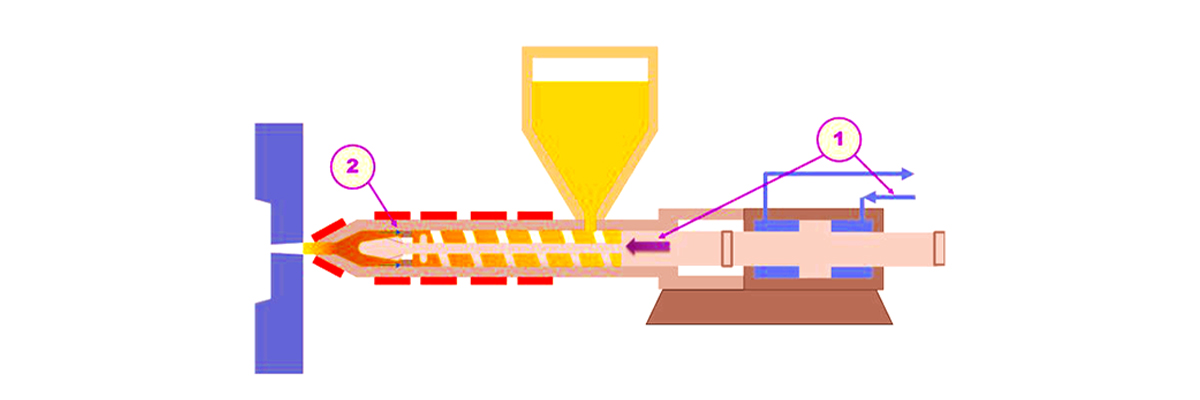

Machine Type Influence

Parts molded with plunger-type injection machines exhibit greater shrinkage rates. This factor should be considered when selecting equipment to balance performance with injection molding cost.

Shrinkage Rate Impact on Injection Molding Cost

Properly managing shrinkage rates through parameter optimization directly affects injection molding cost. Uncontrolled shrinkage can lead to part defects, increased scrap rates, and additional processing steps – all of which drive up costs. By understanding and adjusting the factors that influence shrinkage, manufacturers can produce parts that meet dimensional specifications consistently, reducing waste and minimizing injection molding cost while maintaining quality standards.

II. Flowability

The flowability of molten plastic is a critical factor in determining how well material fills the mold cavity, which directly impacts part quality and injection molding cost. Poor flowability can result in incomplete filling, excessive pressure requirements, and increased cycle times – all of which increase injection molding cost.

1. Influencing Indices

The flowability of thermoplastic materials can be analyzed through several indices that help determine appropriate processing parameters and ultimately influence injection molding cost. These include molecular weight, melt flow rate (MFR), Archimedean spiral flow length, apparent viscosity, and flow ratio (flow path length/part wall thickness).

Materials with lower molecular weight, broader molecular weight distribution, and less regular molecular structure generally exhibit higher melt flow rates, longer spiral flow lengths, and lower apparent viscosity. A higher flow ratio indicates better flowability, which can reduce pressure requirements and potentially lower injection molding cost.

Classification of Common Plastics by Flowability

Good Flowability

- Polyamide (PA)

- Polyethylene (PE)

- Polystyrene (PS)

- Polypropylene (PP)

- Cellulose Acetate (CA)

- Poly-4-methyl-1-pentene

These materials require less injection pressure and can fill complex molds more easily, potentially reducing injection molding cost.

Medium Flowability

- ABS (Acrylonitrile-Butadiene-Styrene)

- AS (Acrylonitrile-Styrene)

- PMMA (Polymethyl Methacrylate)

- POM (Polyoxymethylene)

- PPO (Polyphenylene Oxide)

These materials offer a balance between flow characteristics and mechanical properties, with moderate impact on injection molding cost.

Poor Flowability

- PC (Polycarbonate)

- UPVC (Unplasticized Polyvinyl Chloride)

- PSU (Polysulfone)

- PASF (Polyarylsulfone)

- Fluoroplastics

These materials require higher temperatures and pressures, potentially increasing injection molding cost due to energy requirements and longer cycle times.

2. Molding Conditions

Plastic flowability exhibits varying sensitivity to molding conditions, and mold structure also influences melt flow within the mold. Understanding these relationships is essential for optimizing processing parameters and controlling injection molding cost.

Plasticizing Temperature

Increased material temperature generally improves flowability, though the degree of impact varies by material type.

Materials such as PS (especially impact-resistant grades and those with higher MFR), PP, PA, PMMA, modified polystyrenes (ABS, AS), PC, and CA show significant flowability changes with plasticizing temperature. For these materials, adjusting temperature is an effective way to control flow without substantially increasing injection molding cost.

For PE and POM, plasticizing temperature has a relatively smaller impact on flowability. Careful temperature control remains important for maintaining consistent quality and managing injection molding cost.

Injection Pressure

Increased injection pressure enhances shear effects on the melt, improving flowability. This effect is particularly pronounced for shear-sensitive plastics like PE and POM.

For these materials, adjusting injection pressure can be an effective strategy for controlling flowability. However, higher pressures may increase energy consumption and potentially affect injection molding cost, so a balance must be struck between pressure requirements and economic considerations.

Proper pressure profiling through different stages of the injection cycle can optimize flow while minimizing energy usage, helping to control injection molding cost.

Mold Structure

The design of the gating system (type, size, layout), cooling system, and flow resistance within the mold (including cavity surface finish, runner cross-section, cavity geometry, and venting) all significantly impact actual melt flowability.

A well-designed mold minimizes flow resistance, allowing for lower pressure and temperature requirements, which can reduce injection molding cost. Proper venting prevents air entrapment that can disrupt flow and cause defects, further contributing to injection molding cost efficiency.

Flowability's Impact on Injection Molding Cost

Optimizing flowability is a key factor in controlling injection molding cost. Materials with better flowability generally require lower injection pressures and temperatures, reducing energy consumption. They also allow for faster filling and potentially shorter cycle times, increasing production throughput without increasing injection molding cost proportionally. Properly designed molds that facilitate good flow can reduce scrap rates caused by incomplete filling or flow marks. Conversely, poor flowability often leads to higher energy usage, longer cycles, and increased defects – all of which drive up injection molding cost. By selecting appropriate materials and optimizing processing parameters based on flow characteristics, manufacturers can achieve significant injection molding cost savings while maintaining part quality.

III. Crystallinity

Thermoplastic materials are classified into crystalline and amorphous (non-crystalline) plastics based on whether crystallization occurs during cooling. This characteristic significantly influences processing requirements, part properties, and ultimately injection molding cost.

Crystallization refers to the phenomenon where molecules transition from a freely moving, disordered state in the molten plastic to a state where molecular movement ceases, molecules settle into relatively fixed positions, and there is a tendency for molecules to arrange into a regular pattern. This transition affects material properties and processing requirements in ways that can impact injection molding cost.

Visual Identification of Crystalline vs. Amorphous Plastics

As a general visual guideline for identifying these two categories of plastics, the transparency of thick-walled injection molded parts can be observed:

Crystalline Plastics

Typically opaque or translucent (e.g., POM). They tend to have more predictable shrinkage patterns but require more precise temperature control, which can affect injection molding cost.

Crystalline plastics have a distinct melting point, which means they transition from solid to liquid more abruptly than amorphous materials. This characteristic requires careful temperature management to prevent degradation while ensuring complete melting, both of which impact injection molding cost.

Amorphous Plastics

Generally transparent (e.g., PMMA). They often have better dimensional stability but may be more prone to stress concentration, affecting design considerations and potentially injection molding cost.

Amorphous plastics soften gradually with increasing temperature rather than having a distinct melting point. This property can provide more processing latitude but may require longer cooling times, influencing injection molding cost through extended cycle times.

Exceptions exist: poly-4-methyl-1-pentene is a crystalline plastic with high transparency, while ABS is an amorphous plastic that is not transparent. These exceptions highlight the importance of material testing and proper processing knowledge in managing injection molding cost effectively.

Special Requirements for Crystalline Plastics

When designing molds and selecting injection molding machines for crystalline plastics, the following considerations are crucial, as they directly impact process efficiency and injection molding cost:

Energy Requirements

More heat energy is required to raise material temperature to molding temperature, necessitating equipment with greater plasticizing capacity. This can increase initial investment costs but may not significantly impact ongoing injection molding cost if properly matched to production requirements.

Cooling Requirements

Significant heat is released during cooling and solidification, requiring adequate cooling systems. Efficient cooling design is essential to prevent extended cycle times that would increase injection molding cost.

Density Differences

Greater density difference between molten and solid states leads to higher molding shrinkage and increased risk of sink marks and voids. These defects can increase injection molding cost through rework or scrap.

Cooling Rate Effects

Rapid cooling results in lower crystallinity, reduced shrinkage, and higher transparency. Crystallinity is influenced by part wall thickness, with thicker sections cooling more slowly. Mold temperature control is critical for quality and can impact injection molding cost through energy usage.

Anisotropy and Stress

Significant anisotropy and internal stress are common. Uncrystallized molecules may continue crystallizing after demolding, causing imbalance and potential warpage. This can increase injection molding cost through the need for additional processing or part rejection.

Narrow Processing Window

Crystalline plastics have a narrower plasticizing temperature range, increasing the risk of filling difficulties or gate blockages. This requires more precise process control, which can influence injection molding cost through the need for advanced equipment or more skilled operators.

Crystallinity's Impact on Injection Molding Cost

The crystallinity of plastics has a multifaceted impact on injection molding cost. Crystalline materials generally require more energy for melting and more robust cooling systems, which can increase both energy consumption and equipment investment costs. Their narrower processing window demands more precise temperature and pressure control, potentially requiring more sophisticated machinery and skilled operators – factors that can influence injection molding cost. The higher shrinkage rates and potential for warpage with crystalline materials may increase scrap rates and require additional processing steps, further affecting injection molding cost. However, crystalline plastics often offer superior mechanical properties that may justify these costs for specific applications. Properly managing crystallinity through optimized mold design, cooling systems, and processing parameters is essential for balancing performance requirements with injection molding cost considerations.