Temperature Control in Injection Molding Processes

A comprehensive guide to optimal parameter selection for precision manufacturing, with a focus on design for injection molding principles.

In the realm of injection molding, precise temperature control stands as a cornerstone of product quality and manufacturing efficiency. Effective design for injection molding must incorporate a thorough understanding of how temperature affects material behavior throughout the production cycle. The primary temperature parameters controlled during injection molding include barrel temperature and mold temperature, each exerting significant influence on the final product's characteristics.

Barrel temperature primarily affects plastic melting and flow properties, while mold temperature influences both flow during filling and cooling rates. Additional critical temperature considerations include melt temperature, mold hot runner temperature, material drying temperature, and hydraulic oil temperature. Each of these parameters requires careful monitoring and adjustment to achieve optimal results in design for injection molding applications.

1. Barrel Temperature

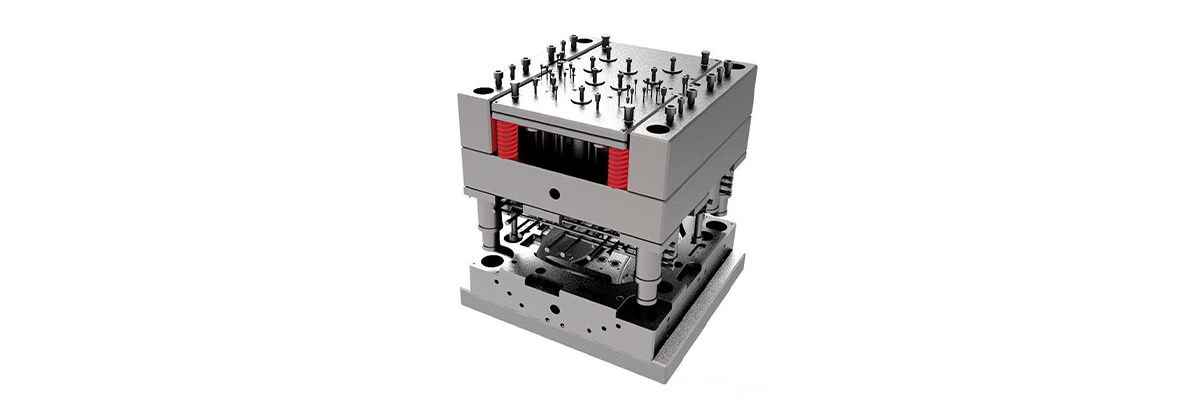

The injection molding machine's barrel and screw form the plasticizing unit responsible for melting the plastic material, with the front part of the barrel connecting to the nozzle. Resistance heating is widely adopted for external heating of the injection molding machine barrel, with heating devices including cast aluminum heaters, ceramic heaters, and mica heaters. These work in conjunction with mechanical shear to achieve steady-state plasticization of the material—a critical aspect of design for injection molding.

Barrel temperature is controlled in segments to achieve the temperature distribution required by the process, along with sufficiently fast heating rates, temperature control accuracy, and energy efficiency. Generally, when the shear heat of the processed plastic is relatively small, the melt temperature can be approximately considered to depend mainly on the barrel heating temperature.

Every plastic has its own melting temperature (or flow temperature). Even the same type of plastic can exhibit different melting and decomposition temperatures due to variations in source or grade, which result from differences in average molecular weight and molecular weight distribution. This variability underscores the importance of material-specific knowledge in design for injection molding.

Barrel Temperature Control System

Modern injection molding machines utilize segmented temperature control to achieve precise heating profiles, essential for optimal design for injection molding outcomes. Each zone can be independently adjusted to accommodate specific material requirements.

When the same product is produced on different types of injection molding machines, the plasticization process differs, and the set barrel temperatures will also vary. The plasticization temperature of the plastic is controlled by the barrel temperature, which directly relates to the plasticization quality—a key factor in successful design for injection molding.

Principles for Setting Barrel Temperature

- Ensure good plasticization of the plastic, enabling smooth injection without causing local degradation of the plastic. This principle is fundamental to maintaining material integrity in design for injection molding.

- Temperature setting is primarily related to the characteristics of the plastic. Generally, the plastic must be heated above its viscous flow temperature Tf (or melting point Tm) to enable flow and injection. Therefore, the maximum temperature at the end of the barrel should be higher than Tf or Tm but must be lower than the plastic decomposition temperature Td. Understanding these temperature ranges is critical for effective design for injection molding.

- For heat-sensitive plastics with a narrow temperature range between Tf and Td, as well as plastics with lower molecular weight and wider molecular weight distribution, the barrel temperature should be set to a lower value, i.e., slightly higher than Tf. For plastics with a wider temperature range between Tf and Td and higher molecular weight, higher temperatures can be appropriately selected to take advantage of their lower viscosity characteristics—an important consideration in design for injection molding.

- The residence time of the plastic in the barrel must be considered, especially for heat-sensitive plastics such as polyoxymethylene. Therefore, in production, in addition to strictly controlling the maximum barrel temperature, the residence time of the plastic in the barrel (i.e., the influence of the production cycle on material temperature) should also be controlled. This timing factor is crucial in design for injection molding to prevent material degradation.

-

The structural characteristics of the product and mold should be considered:

- When molding thin-walled products, the flow resistance of the plastic is very high, and it is easy to cool and lose flowability. Therefore, higher barrel temperatures should be selected.

- When molding thick-walled products, the flow resistance is small, and because thick-walled products require longer cooling times, the injection molding cycle increases, and the plastic is heated in the barrel for a longer time. Therefore, lower temperatures should be selected.

- For products with complex shapes or with inserts, where the melt flow path is long and tortuous, higher barrel temperatures should be selected to ensure complete filling—an essential aspect of design for injection molding.

-

Barrel temperature control also varies for plastics with different properties, as exemplified by ABS and PC:

- The viscosity of ABS is relatively unaffected by temperature. Therefore, once ABS reaches its deformation flow temperature, further increasing the barrel temperature to reduce viscosity and aid mold filling has little effect. This is particularly detrimental when manufacturing colored ABS parts, as most color pigments are organic compounds that are unstable at high temperatures, easily causing uneven color spots in the product—a critical consideration in design for injection molding of aesthetic components.

- In contrast to ABS, the viscosity of PC decreases significantly with a slight increase in temperature. According to data, within the processing temperature range, increasing the barrel temperature by 10-20°C can reduce the injection pressure by half. Conversely, if the temperature is 10-20°C lower than the normal processing temperature, the injection pressure doubles. This effect is particularly pronounced when the nozzle and mold temperatures are low, so sufficient material temperature and mold temperature must be ensured when producing PC parts—an important distinction in design for injection molding of PC components.

- Experientially, the suitability of material temperature can be judged by observing open injection at low pressure and speed. Proper material temperature produces an injection that is strong, bubble-free, non-curling, shiny, and continuous. Reference values for mold and barrel temperatures for different plastics can be found in Table 2-1, which serves as a valuable resource in design for injection molding.

- The nozzle temperature is set slightly lower than the maximum barrel temperature. As the melt passes through the nozzle, the shear rate further increases the melt temperature. Additionally, to prevent drooling of the molten plastic, the nozzle temperature is usually 5-10°C lower than the maximum barrel temperature—an important detail in design for injection molding to maintain process control.

Temperature Ranges for Common Plastics

Table 2-1: Mold and Barrel Temperatures for Different Plastics

| Plastic Type | Barrel Temperature Range (°C) | Mold Temperature Range (°C) | Design Considerations |

|---|---|---|---|

| ABS | 180-250 | 40-80 | Temperature has minimal effect on viscosity; important for color stability in design for injection molding |

| PC | 260-320 | 80-120 | Temperature significantly affects viscosity; critical control for design for injection molding success |

| PP | 170-220 | 20-60 | Wide processing window; suitable for various design for injection molding applications |

| PE | 150-200 | 20-50 | Low viscosity sensitivity to temperature; good flow properties for complex design for injection molding |

| PA6 | 230-280 | 40-80 | Hygroscopic; requires drying before processing in design for injection molding |

| POM | 180-210 | 80-120 | Heat-sensitive; residence time critical in design for injection molding |

Successful implementation of these temperature principles requires a holistic approach that integrates material science, machine capabilities, and product requirements—all core elements of effective design for injection molding. Engineers must not only understand the theoretical temperature ranges but also develop a practical sense for how these parameters interact in real-world production environments.

In modern manufacturing facilities, computerized control systems have greatly enhanced temperature management capabilities, allowing for precise monitoring and adjustment of all critical zones. This technological advancement has significantly improved the consistency and repeatability of injection molding processes, making design for injection molding more predictable and reliable.

Advanced Temperature Monitoring

Modern injection molding machines feature sophisticated temperature monitoring systems that provide real-time data on all critical zones. This level of control is essential for maintaining process stability and achieving the design specifications in design for injection molding projects. Operators can set precise temperature profiles and receive instant alerts if any parameter deviates from the optimal range, enabling quick adjustments and minimizing waste.

The importance of temperature control extends beyond the immediate production cycle, impacting downstream processes such as assembly and finishing. Properly controlled temperatures result in parts with consistent dimensions and properties, reducing the need for rework and ensuring better fit and function in final assemblies—a key objective of design for injection molding.

Continuous improvement in temperature control technology, combined with a deeper understanding of material behavior, has expanded the possibilities of what can be achieved through injection molding. Complex geometries, thin walls, and tight tolerances that were once considered challenging are now routinely produced with high quality, thanks to advancements in both equipment and design for injection molding methodologies.

As sustainability becomes an increasingly important consideration in manufacturing, optimized temperature control also plays a role in reducing energy consumption. By precisely maintaining only the necessary temperatures and avoiding excessive heating, manufacturers can minimize energy use while still achieving excellent results—an environmentally responsible approach to design for injection molding.

Ultimately, mastering temperature control in injection molding requires a combination of technical knowledge, practical experience, and attention to detail. By following established principles while remaining adaptable to specific material and product requirements, manufacturers can consistently produce high-quality parts that meet or exceed design expectations— the ultimate goal of design for injection molding.