Precision Injection Molding Service for Advanced Manufacturing

Delivering high-quality, cost-effective injection molding solutions with cutting-edge technology and expertise. Our injection molding service caters to diverse industries with precision and efficiency.

Production Yield

Years of Experience

Clients Served

Molds Produced

Our Comprehensive Injection Molding Service

We offer end-to-end injection molding solutions tailored to your specific needs, from design and prototyping to full-scale production.

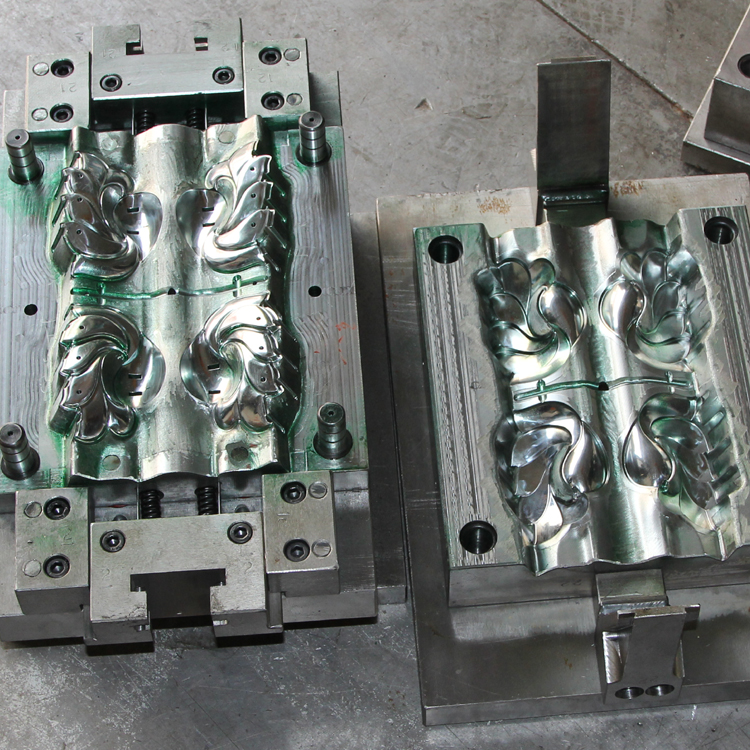

Precision Mold Design

Our expert engineers create highly precise molds using advanced CAD/CAM software, ensuring optimal performance for your injection molding service requirements.

- 3D modeling and simulation

- Mold flow analysis

- Prototype validation

High-Volume Production

Our state-of-the-art facility is equipped to handle high-volume production runs with consistent quality and efficiency for your injection molding service needs.

- Automated production lines

- Real-time quality monitoring

- Capacity up to 10 million parts/year

Material Science Expertise

We provide expert material selection guidance to ensure optimal performance, durability, and cost-effectiveness for your injection molding service project.

- Thermoplastics and engineering resins

- Composites and specialty materials

- Sustainable and recycled options

Precision Micro-Molding

Our micro-injection molding service capabilities enable production of extremely small, high-precision components for medical, electronics, and other industries.

- Parts as small as 0.1g

- Tolerance control down to ±0.001mm

- Medical-grade precision

Overmolding & Insert Molding

Our advanced overmolding and insert molding service capabilities allow for complex, multi-material components in a single production process.

- Multi-material bonding

- Metal-plastic integration

- Elastomer overmolding

AI-Enhanced Quality Control

Our injection molding service incorporates AI-driven quality control systems to ensure consistent part quality and minimize defects.

- Machine learning defect detection

- Real-time process optimization

- Predictive maintenance

Advanced Injection Molding Technology

Our state-of-the-art equipment and processes ensure the highest quality for your injection molding service requirements.

Computer-Aided Engineering

We utilize advanced CAE software to simulate and optimize the injection molding process before production begins. This technology allows us to identify potential issues early, reducing development time and costs for our injection molding service clients.

Mold Flow Analysis

Predict melt behavior and optimize fill patterns

Cooling Simulation

Optimize and optimize cooling channel efficiency

Warp Analysis

Predict and prevent part deformation

Structural Analysis

Validate part performance under stress

Industry 4.0 Integration

Our injection molding service incorporates Industry 4.0 technologies, including IoT sensors, real-time monitoring, and data analytics to optimize production processes and ensure consistent quality.

Real-time Process Monitoring

Continuous monitoring of temperature, pressure, and cycle times

Predictive Analytics

AI algorithms predict maintenance needs and potential issues

Cloud-based Data Management

Secure storage and analysis of production data

Injection Molding Materials

Our injection molding service offers a wide range of materials to meet your specific application requirements, from standard thermoplastics to high-performance engineering resins.

Polypropylene (PP)

A versatile, cost-effective material with excellent chemical resistance and good mechanical properties, ideal for a wide range of injection molding service applications.

Acrylonitrile Butadiene Styrene (ABS)

A popular engineering plastic offering a good balance of strength, toughness, and rigidity, suitable for many injection molding service applications requiring impact resistance.

Polycarbonate (PC)

A high-performance plastic with excellent impact resistance, transparency, and heat resistance, ideal for demanding injection molding service applications.

Nylon (PA)

A strong, durable material with excellent wear resistance and mechanical properties, suitable for high-stress injection molding service applications.

Polyethylene (PE)

A lightweight, flexible material with excellent chemical resistance and low moisture absorption, suitable for many injection molding service applications.

Polystyrene (PS)

A rigid, transparent material with good dimensional stability and easy processability, suitable for many injection molding service applications.

Material Selection Guide

Choosing the right material is crucial for the success of your injection molding service project. Our experts can help you select the optimal material based on your specific requirements.

| Material | Strength | Heat Resistance | Chemical Resistance | Impact Resistance | Cost |

|---|---|---|---|---|---|

| Polypropylene (PP) |

|

|

|

|

|

| ABS |

|

|

|

|

|

| Polycarbonate (PC) |

|

|

|

|

|

| Nylon (PA) |

|

|

|

|

|

Injection Molding Process Parameters

Our injection molding service utilizes precise control of process parameters to ensure consistent part quality and production efficiency.

Key Process Parameters

The injection molding process involves several critical parameters that must be carefully controlled to produce high-quality parts. Our injection molding service experts optimize these parameters for each specific application.

Controls the rate at which molten plastic fills the mold cavity. Higher speeds can improve surface finish but may cause shear heating.

The force applied to push molten plastic into the mold. Must be sufficient to fill the cavity but not so high as to cause flashing or excessive stress.

The temperature of the mold during the injection process. Affects part cooling rate, crystallinity, and surface finish.

The time allowed for the part to cool before ejection. Must be sufficient to ensure dimensional stability but not excessive to impact cycle time.

Drying Requirements for Common Materials

| Material | Max Moisture Content | Drying Temperature | Drying Time |

|---|---|---|---|

| ABS | 0.1% | 70-90°C | 2-4 hours |

| PC | 0.02% | 90-120°C | 2-4 hours |

| PA | 0.04-0.08% | 85-120°C | 2-4 hours |

| PC/ABS | 0.04% | 80-110°C | 2-4 hours |

| PET | 0.02% | 120-165°C | 4 hours |

Process Optimization Benefits

-

Reduced scrap rate by up to 90%

-

Improved part consistency and quality

-

Shortened cycle times by 15-30%

-

Extended mold life

-

Lower energy consumption

Injection Molding Process Animation

The following animation demonstrates the injection molding process, showing how molten plastic is injected into a mold, cooled, and ejected as a finished part. Our injection molding service utilizes this process with advanced controls for precision and efficiency.

Injection

Molten plastic is injected into the mold cavity

Packing

Additional pressure is applied to ensure full cavity filling

Cooling

The part cools and solidifies in the mold

Ejection

The finished part is ejected from the mold

Injection Molding Applications

Our injection molding service caters to a wide range of industries, providing custom solutions for diverse applications.

Automotive

Our injection molding service provides high-precision components for the automotive industry, including interior parts, exterior components, and under-the-hood applications.

Medical

We offer precision injection molding service for medical devices, with cleanroom facilities and strict quality control to meet regulatory requirements.

Electronics

Our injection molding service produces high-precision components for the electronics industry, including enclosures, connectors, and heat sinks.

Packaging

We provide injection molding service for packaging applications, including closures, containers, and custom packaging solutions.

Consumer Goods

Our injection molding service produces a wide range of consumer goods, from household items to toys and personal care products.

Industrial

We offer injection molding service for industrial applications, including machinery parts, valves, and hydraulic components.

Quality Control in Injection Molding

Our injection molding service implements rigorous quality control measures to ensure every part meets or exceeds customer specifications.

Comprehensive Quality Assurance

Our injection molding service quality control process begins with raw material inspection and continues through every stage of production, ensuring consistent quality and reliability.

Advanced Inspection Equipment

We utilize coordinate measuring machines (CMM), optical comparators, and other advanced equipment to verify part dimensions and quality.

Statistical Process Control (SPC)

Our injection molding service implements SPC to monitor and control production processes, ensuring consistent quality and reducing variability.

AI-Powered Defect Detection

We use machine learning algorithms to detect even the smallest defects, ensuring only high-quality parts leave our facility.

Quality Certifications

Our injection molding service is ISO 9001, IATF 16949, and ISO 13485 certified, demonstrating our commitment to quality excellence.

Quality Performance Metrics

First Pass Yield

Sigma Level

Dimensional Tolerance

On-Time Delivery

Industry Research on Injection Molding Quality

"Injection molding has moved from pilot projects to core process control. Modern AI no longer serves as a separate analytical layer; it is directly integrated with injection molding machines and controllers to achieve closed-loop optimization. In practice, this means leveraging high-frequency sensor data to train models to predict defects, recommend parameter adjustments, or autonomously adjust setpoints mid-cycle."

Source: "Injection Molding Trends in 2025: AI and Smart Production Workflows" - TopStar Machine, 2025 https://www.topstarmachine.com/injection-molding-trends-in-2025-ai-and-smart-production-workflows/

Injection Molding Case Studies

Explore our successful injection molding service projects and see how we've helped clients achieve their manufacturing goals.

Lightweight Component Production

Our injection molding service helped an automotive manufacturer reduce component weight by 30% while maintaining structural integrity, resulting in improved fuel efficiency.

Precision Medical Device Components

We provided injection molding service for a medical device manufacturer, producing ultra-precise components with tolerances as tight as ±0.001mm.

High-Volume Consumer Electronics Parts

Our injection molding service supported a consumer electronics company in scaling production of a new product line, achieving 10 million parts with consistent quality.

Frequently Asked Questions

Find answers to common questions about our injection molding service.

What is injection molding?

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure, cooled, and then ejected as a finished part. Our injection molding service utilizes this process to produce high-quality plastic components for various industries.

What materials can be used in injection molding?

Our injection molding service supports a wide range of materials, including thermoplastics (such as PP, PE, ABS, PC, and PA), thermoset plastics, and specialty materials like liquid silicone rubber (LSR). The choice of material depends on the application requirements such as strength, temperature resistance, chemical resistance, and appearance.

What is the typical lead time for injection molding service?

Lead times for our injection molding service vary depending on the complexity of the part and the production volume. Typically, mold design and fabrication take 4-8 weeks for standard molds, while production lead times range from 2-4 weeks for medium-volume orders. We offer expedited options for urgent projects.

What are the cost factors for injection molding?

The cost of our injection molding service depends on several factors, including mold cost (determined by complexity, size, and material), material cost, production volume, part complexity, and finishing requirements. Generally, higher production volumes result in lower per-unit costs due to economies of scale.

How do you ensure quality in your injection molding service?

Our injection molding service implements a comprehensive quality control system that includes material inspection, in-process monitoring, and final part inspection. We use advanced equipment such as coordinate measuring machines (CMM) and optical comparators to verify dimensions, and AI-powered systems to detect defects. We are ISO 9001, IATF 16949, and ISO 13485 certified, demonstrating our commitment to quality.

Can you handle large production volumes?

Yes, our injection molding service is equipped to handle large production volumes. Our facility features automated production lines with robotic part handling, allowing us to efficiently produce millions of parts annually. We also implement lean manufacturing principles to optimize production flow and minimize waste.

Injection Molding Glossary

Key terms and concepts related to our injection molding service.

Cycle Time

The total time required to complete one injection molding cycle, including injection, packing, cooling, and ejection. Our injection molding service optimizes cycle times to maximize production efficiency.

Mold Cavity

The hollow space in the mold that shapes the molten plastic into the desired part. Our injection molding service can produce molds with single or multiple cavities depending on production requirements.

Gate

The opening through which molten plastic enters the mold cavity. The design and location of the gate significantly impact part quality in our injection molding service.

Draft Angle

A slight taper applied to mold surfaces that are perpendicular to the direction of mold opening, allowing for easier part ejection. Our injection molding service incorporates appropriate draft angles into all mold designs.

Flash

Excess plastic that escapes from the mold cavity during injection, typically occurring at the parting line. Our injection molding service implements strict process controls to minimize or eliminate flash.

Sink Marks

Surface depressions caused by uneven cooling or shrinkage of the plastic. Our injection molding service uses advanced cooling system design and process optimization to prevent sink marks.

Warpage

Part deformation caused by uneven shrinkage during cooling. Our injection molding service addresses warpage through proper material selection, mold design, and process parameter optimization.

Overmolding

A process where one material is molded over another to create a single part with multiple materials or colors. Our injection molding service offers both two-shot and insert overmolding capabilities.

Ready to Start Your Injection Molding Project?

Our injection molding service experts are ready to help you bring your project to life with precision, quality, and efficiency.